Ok so my worries over missing parts were unfounded, as it turns out the voltage doubler board is for countries that have 110V AC mains supply, obvious really but as I am a novice at HV electronics these sorts of issues are bound to trip me up.

Thankfully Valery of Emotorwerks clarified the confusion as soon as I sent him a photo of my kit unpacked, there was 1 part missing however an output diode, Valery sent me a link to the part so I could confirm that the part was definitely missing (which it was)

In fact the service I have received so far from Valery of Emotorwerks is second to none, Thanks Valery, We shall probably be doing more business in the future (when I start my second EV build, whoa there slow down boy one at a time!)

Will get more photos uploaded soon as soon as I can find the micro usb lead for my other camera.

I am really starting to enjoy this build now.

Monday 17 June 2013

Friday 14 June 2013

Charger build woes

Ok so I finally got serious

with the charger build last night and discovered that I am definitely missing

some considerable bits, even more worrying is that the Ali box I have just had

made to accommodate the charger might now be too small for the missing bits! I

emailed Valery of Emotorwerks yesterday and his reply suggests that I should

have had a Voltage Doubler board as I am using single phase and it appears that

I have been sent the 3 Phase kit by mistake.

The missing Doubler

board is large to say the least and has a lot of large Caps on it looks like I

may have to rethink the chargers internals completely once I have this board

& bits, even then it may not fit and I might have to scrap the box and

start again with a new Ali box for the charger (I hope not as the missus will

not be pleased!) also the box was made as large as I could fit in the mini boot

on the Honda so a larger box is not really an option.

However there is a space to the left of the charger in front of the Soliton that would probably take the extra board/s (there may be two) if I can make an extra box to accommodate the Voltage Doubler and connect the two via some cabling this might just work, it is sort of a bodge but with the very limited boot space I don't have a lot of options.

There were also a number of smaller components missing but none of these are size limiting and Valery was happy to send whatever was missing along with some wire as well as some compensation for the extra duty I am bound to get charged.All in all I am not too worried about any of this but as we approach the 10K self-imposed limit on this project my partner is starting to twitch ;-) I have around £1200 left before I break the 10K barrierTo be honest I can’t believe she ever let me start this project but I am sure I will be paying for it in kind for years to come :-)

However there is a space to the left of the charger in front of the Soliton that would probably take the extra board/s (there may be two) if I can make an extra box to accommodate the Voltage Doubler and connect the two via some cabling this might just work, it is sort of a bodge but with the very limited boot space I don't have a lot of options.

There were also a number of smaller components missing but none of these are size limiting and Valery was happy to send whatever was missing along with some wire as well as some compensation for the extra duty I am bound to get charged.All in all I am not too worried about any of this but as we approach the 10K self-imposed limit on this project my partner is starting to twitch ;-) I have around £1200 left before I break the 10K barrierTo be honest I can’t believe she ever let me start this project but I am sure I will be paying for it in kind for years to come :-)

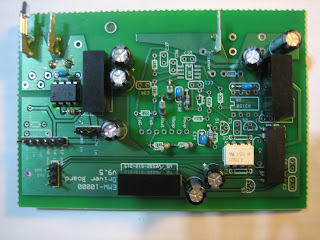

EMotorWerks 10KW Charger Non-PFC Kit fresh out the box

Aluminum battery boxes finally built

At last I found a local sheet metal fabricator that was happy to use my old sheets of aluminum (well my partner did anyhow as she is definitely in control of the finances on this project), David from Sussex Iron Works, literally just down the road from me.

After supplying him with the hand drawn technical drawing that Mikki (My Partner) had kindly produced from Brents rough sketch, he got straight to work on them the next day, the day after that they were done and for less than half the price I was originally quoted (£200 to be exact) this is great as not only did I save money but got to use some very old sheet Ali I have had kicking around for years.

I will post photos of these soon as well.

I took the boxes straight back to Brent for sizing up against the car so we can work out exactly where the Ali angle needs fitting to give us a mounting solution.

Brent was on holiday that week so I caught up with him the following week and talked at length on the next stage in the build.

Brent advised me of the need to make up a steel support frame to hold the battery boxes securely in place, I had originally thought that we could just mount the angle Ali straight onto the car but as Brent explained this would be very insecure and in the event of a crash would definitely not be good enough to prevent the battery’s flying out everywhere ( I am learning more every day on this project).

He has ordered the Steel and it should be here on Friday (Today in fact) his next free slot for the EV project was next Wednesday and he reckoned that it should not take more than a day to make up the steel support and size up the boxes ready for TIG welding of the Ali Brackets, so they should be ready for battery stuffing the week after that (hopefully)

After supplying him with the hand drawn technical drawing that Mikki (My Partner) had kindly produced from Brents rough sketch, he got straight to work on them the next day, the day after that they were done and for less than half the price I was originally quoted (£200 to be exact) this is great as not only did I save money but got to use some very old sheet Ali I have had kicking around for years.

I will post photos of these soon as well.

I took the boxes straight back to Brent for sizing up against the car so we can work out exactly where the Ali angle needs fitting to give us a mounting solution.

Brent was on holiday that week so I caught up with him the following week and talked at length on the next stage in the build.

Brent advised me of the need to make up a steel support frame to hold the battery boxes securely in place, I had originally thought that we could just mount the angle Ali straight onto the car but as Brent explained this would be very insecure and in the event of a crash would definitely not be good enough to prevent the battery’s flying out everywhere ( I am learning more every day on this project).

He has ordered the Steel and it should be here on Friday (Today in fact) his next free slot for the EV project was next Wednesday and he reckoned that it should not take more than a day to make up the steel support and size up the boxes ready for TIG welding of the Ali Brackets, so they should be ready for battery stuffing the week after that (hopefully)

Subscribe to:

Posts (Atom)